Getting to next generation accuracy – Noise, heat and isolation

by Anoop Gangadharan January 21, 2019In the development of the next generation of precision power analysis solutions, engineers at Yokogawa had their work cut out. After all, it was vital for the upcoming flagship power analyzer to succeed its predecessors to deliver the worlds greatest measurement accuracy. For many industries, minor deviations in uncertainty specifications can be the difference between success & failure from a variety of perspectives including safety, efficiency, performance and compliance.

Noise and isolation:

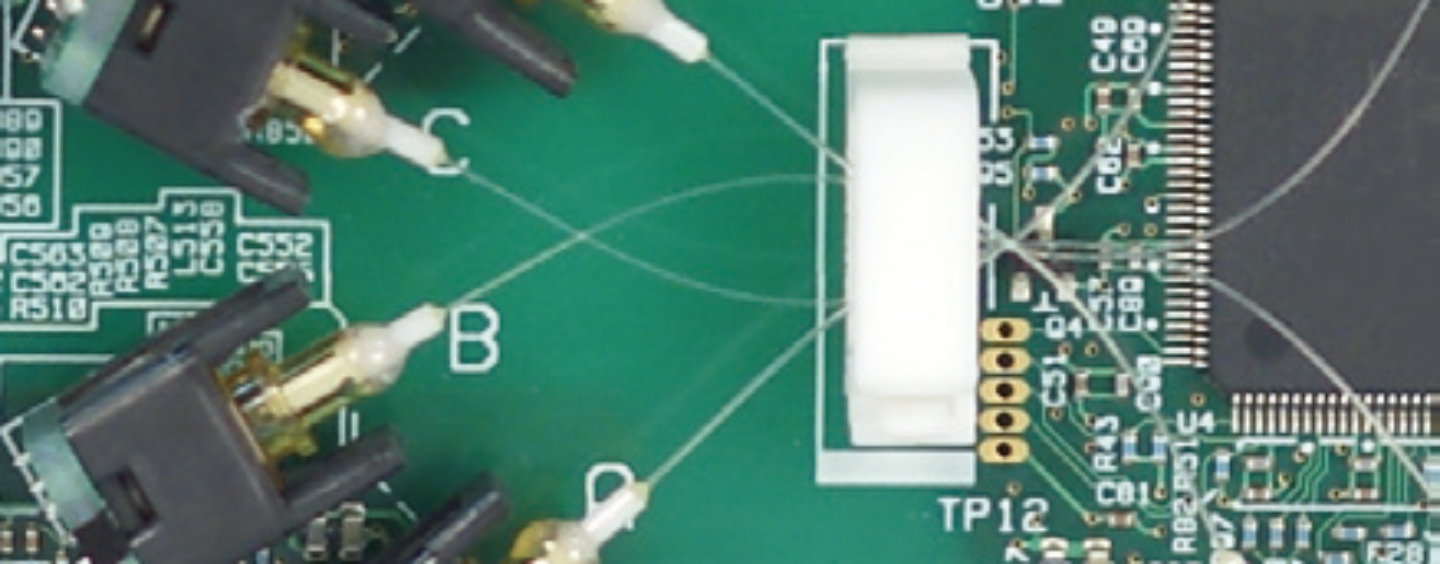

When building the world’s most accurate power analyzer, it is vital to reduce the amount of noise, improve isolation to reduce inter component interference.”Considering that we were moving into a modular architecture with plug and play modules, we needed to ensure that we achieved excellent isolation within and outside the individual modules and their components -notes Eiichi Odaira who led the global launch of the WT5000. “We therefore built upon our ispro optical isolation technology from the DL850 and PX8000. This helped us achieve significant noise reduction and high speed data communication – to reach our targeted 10MS/s data transfer speed.”

To achieve this however, a thorough analysis of noise flow routes were carried out first following which, several parts of isolation shields were strengthened through optical transmission and noise routes were enhanced to ensure that the circuitry wasn’t affected.

“To achieve the WT5000’s high sampling rate, the isoPRO technology, a high-speed and high-voltage isolation technology using optical transmission, was enhanced. Originally developed for the isolation module of the DL850, this enabled high-voltage isolation of 1000 Vrms.

Internal power consumption and heat flows – the balance between Channel count, accuracy

Accuracy and noise reduction – Accommodating more channels in the same size main frame as the WT3000E but with higher accuracy was a challenge.

Besides the input design, there are two key criteria for high accuracy which are heat and (common mode) noise. Especially as the input modules are user swappable, the heat distribution inside the instrument must be equal over the whole instrument.

To achieve this, the heat dissipation routes were analyze following which the mounting mechanism of the heat exhaust fans and heat dissipation routes were improved.

“We improved and designed special shielding against noise and crosstalk, to maintain the same high performance in the smaller module input size. But this shielding also made it more difficult to dissipate the heat of the measurement. Therefore a lot of effort went into testing and evaluating on the heat distribution throughout the WT5000”.

DC accuracy

For DC accuracy and capturing of the high switching frequency precisely. We needed to improve the sample speed and bit resolution. After selecting the right 18bit 10 MHz A/D converter, with extremely low noise level. We needed to design the analogue front end to match the higher voltage level which is required to make the best use of the A/D converter capabilities. The next challenge was to have the isolation of the input module work with this high resolution & high sample speed. There for we implemented our IsoPro optical isolation technology in to the WT5000.

Learn more about the world most accurate power analyzer WT5000.