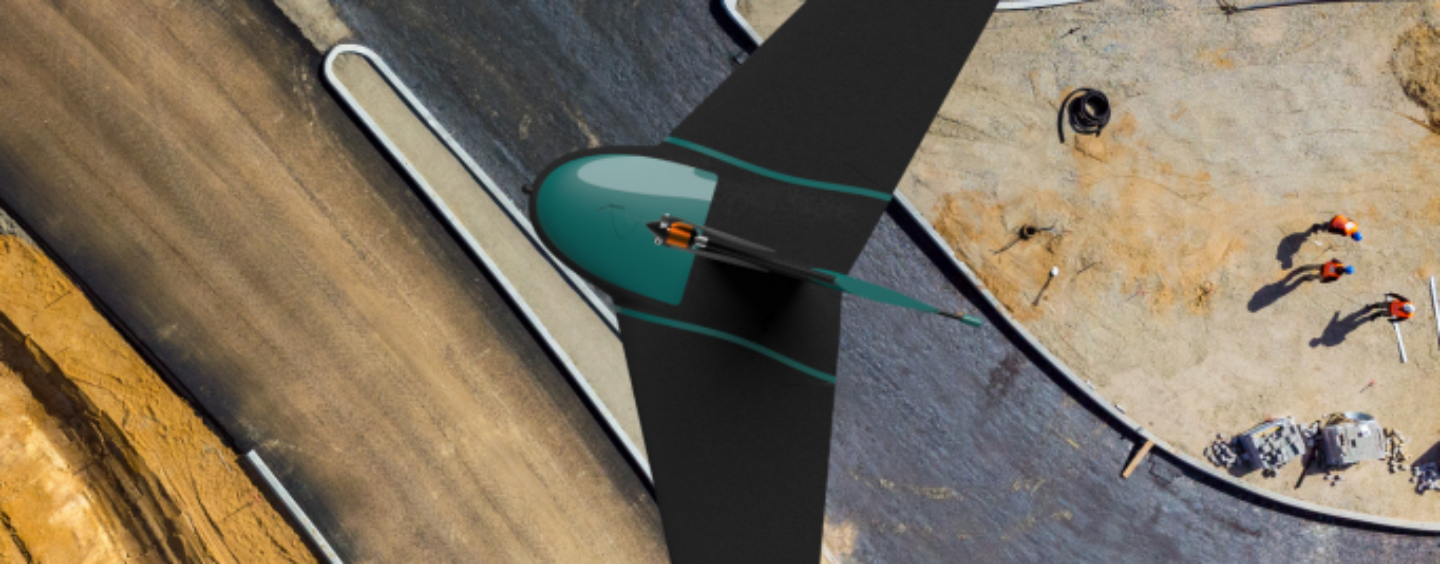

Atmos UAV is starting a revolution in the drone market with the introduction of Marlyn, its industrial grade photogrammetry drone that simplifies and optimizes surveying processes. Atmos UAV was founded in 2013 and in Marlyn, has manufactured the world’s first drone to combine Vertical Take Off and Landing (VTOL) and forward flight in a fully autonomous flight. Combining the flexibility of a multirotor ‘quadcopter’ style drone with the efficiency and speed of a fixed-wing drone , Marlyn safely performs airborne surveying and mapping projects in any terrain and in almost any weather.

Designed for vertical take off and landing

Capable of operating safely and reliably in wind speeds up to 45km/h (6 Bft), Marlyn’s hybrid rotor/fixed-wing design allows it to fly efficiently at high speed like a conventional fixed-wing drone. This means that, in a single flight, Marlyn can typically scan an area of 12km2 before its batteries are discharged. By comparison, a conventional quadcopter-style drone can only scan an area of 0.5km2 per flight. Unlike a conventional fixed-wing drone, however, Marlyn can take off vertically and land vertically on the same spot. Conventional fixed-wing drones require a runway for take-off and landing, or inconvenient auxiliary devices such as catapults, landing pads or nets. The VTOL capability of Marlyn means that it offers much greater flexibility when used in the field. It may be launched from almost anywhere, and all the equipment needed for a flight can be carried by a single operator in its dedicated backpack. This superior flying performance means that surveyors can dramatically reduce flying time per square kilometer surveyed, and thus achieve higher productivity and a lower cost of operations. Marlyn is in use worldwide today in numerous surveying, mapping and geospatial data-gathering operations by organizations in the mining, agriculture, forestry and construction industries, and by government agencies.

Journey to the top

The professional drone market is extremely competitive, and hundreds of innovative manufacturers are continually developing and refining new products. Time to market and performance were key determinants of Atmos’ success with the Marlyn product. This meant that the set-up for motor/propeller testing had to meet the twin conditions of speed and accuracy. The engineering requirement was to measure power dissipation in the drivetrain given a known power input and a known rotor speed (rpm) measurement. The challenge for the Atmos engineers was to achieve highly accurate measurement results while keeping the test time for each motor/propeller combination as short as possible. Using a precision power analyzer from Yokogawa helped Atmos to not only reduce the testing time for a single motor from 4 hours to 30 minutes but also get verifiably accurate results. Dirk Dokter Technical Director & Founding Partner of Atmos says “I did not have to worry about the (Yokogawa) WT1800E on this score – I had total confidence in the values displayed on screen.” Exhaustive testing of hundreds of motor/propeller combinations enabled Atmos to find the ideal configuration for the diverse operating conditions to which the drone would be exposed.

Acelerated motor testing

Dirk Dokter Technical Director & Founding Partner of Atmos says: ‘The Marlyn design has exceeded our expectations in terms of reliability. That’s not just in normal operation – because of the results from our power dissipation testing, we know that we can produce more thrust without risk of the drive overheating. We have a safety margin over and above what’s required in normal operation. That’s very important for us, because our name is on the aircraft, and the Atmos brand stands for reliability and performance.’

Download the case study to learn how Atmos UAV uncovered the ideal combination of propeller and motor to ensure reliable performance for the Marlyn under each operating condition.

Check for the most recent information regarding Yokogawa precision power analyzers and learn about the newest WT5000 – a versatile platform that delivers extraordinary precision and exceptional performance for the most demanding applications.

No Comments so far

Jump into a conversationNo Comments Yet!

You can be the one to start a conversation.